Productivity increase with RFID Kanban

Productivity increase with RFID Kanban

RFID Kanban: Save time and reduce costs.

- RFID Kanban supply with our brand CPS® (C-Product Service)

- C-parts supply using Radio Frequency Identification.

- Radio transmission of the item and bin data directly from the customer's production facility to the central Würth Industrie Service warehouse

- Early recognition of demand fluctuations

- Automated repeat orders without the need for scanning or manual entry

- Maximum supply security

The technique is explained quickly: The basis is an insensitive chip with antenna, referred to as a so-called RFID tag or RFID transponder, which is attached to the respective object, in the C-Parts area as a label on the Kanban bin, and is movable. Each tag is identifiable by a unique number for data security. An RFID system also consists of a reading device for detecting the transponder and the sending unit for data transmission or for the automated reordering of C-Parts for production. The essential distinction of the systems lies in passive or active RFID transponders.

While passive RFID transponders do not have their own power supply and gain the energy to send the data from the energy field generated by the reader, active transponders have their own energy source, for example battery, which initiates the data transfer.

Würth Industrie Service operates both systems, but mainly favors systems with passive RFID transponders, as these are maintenance-free. In addition, the integration of systems with passive transponders is seamlessly possible and no change in customer processes necessary.

iDISPLAY

The digital shelf label displays all item information, enables reordering at the push of a button, and offers a pick-by-light function when used with the iTERMINAL.

iTERMINAL: the digital information point

The screen displays all information about the Kanban rack at a glance and enables item search via pick-by-light in combination with the iDISPLAY.

iSCALE and iSCALE pal

The two weighing systems send a demand notification as soon as a defined weight threshold is undershot. iSCALE is a sensor-controlled scale directly connected to a Kanban bin. iSCALE pal uses the same technology for pallets and accommodates up to 64 bins.

Kanban information platform WIS Portal

The specially developed WIS Portal provides you with complete transparency in the Kanban process! Bin status, item location, and fill quantities, as well as consumption analyses and turnover volumes, can be accessed at any time with just a few clicks. Additionally, the system gives you access to material and certificate data, as well as invoices, delivery notes, order notifications, and item data lists.

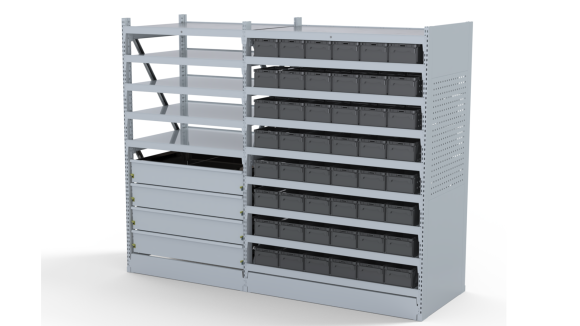

CPS®Kanban flex: the flexible Kanban rack

Our self-developed Kanban rack impresses with its stability, sturdiness, and flexibility.

Kanban bins

Our Würth small load carriers according to VDA standards can be perfectly combined and offer optimal storage solutions for a wide variety of items. With our bins, you make the most of your available storage space.

RFID Kanban in action: Success stories from our customers

You might find this interesting:

- Brochure CPS®RFID Kanban

- Brochure Connected Systems

- Download center with our

product and system brochures

product and system brochures

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.