C-Parts. With Certainty.

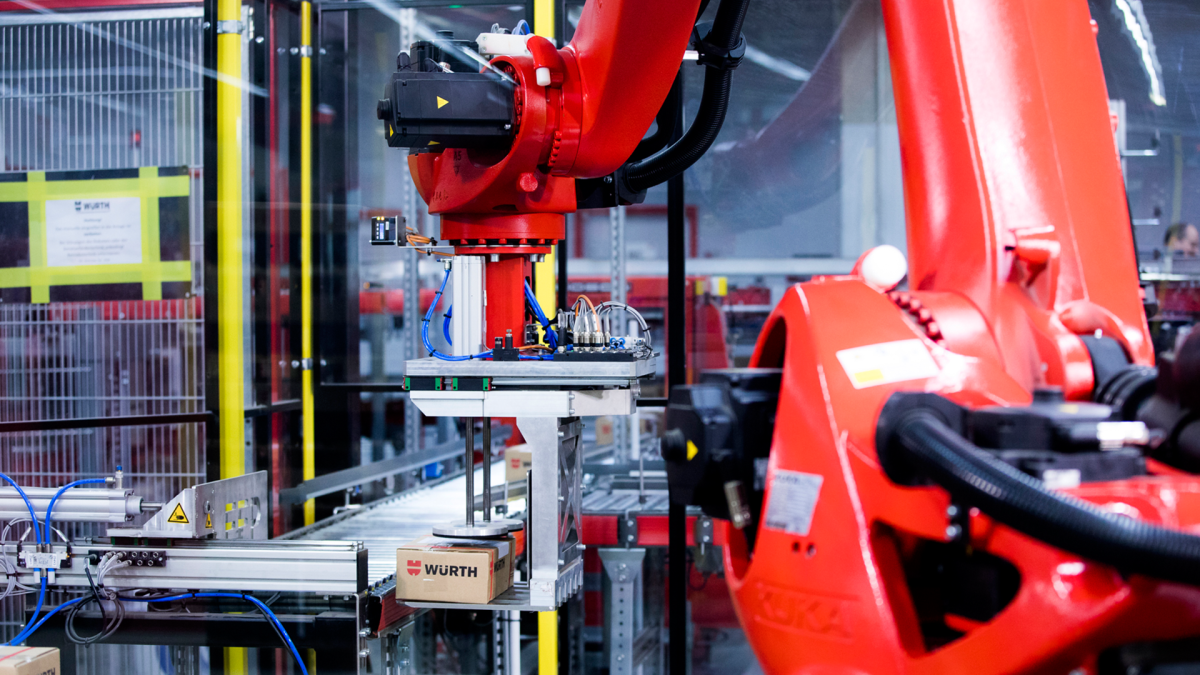

Würth Industrie Service is certainly your reliable partner for C-Parts. We ensure that you, as our customer, have the right quantity of small parts with the right quality for your production requirements at the right time and at the right point of use (Six-R rule). It is precisely this reliability aspect that makes our customers trust our solutions.

You might find this interesting:

- C-Parts. With Certainty. - the brochure

- Download centre with our

product and system brochures

product and system brochures

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.