Kanban: The smart method to optimise your production processes

The highly flexible Kanban systems offered by Würth Industrie Service under our CPS® KANBAN service brand help you to make your warehouse and production effective and transparent. Kanban systems are used to supply indirect materials – mainly by major industrial customers for the manufacturing of machines and products as well as for other production processes.

Learn more about how the Kanban principle, Kanban systems, RFID systems and related solutions from Würth Industrie Service help you to optimise your production processes.

Kanban system and principle

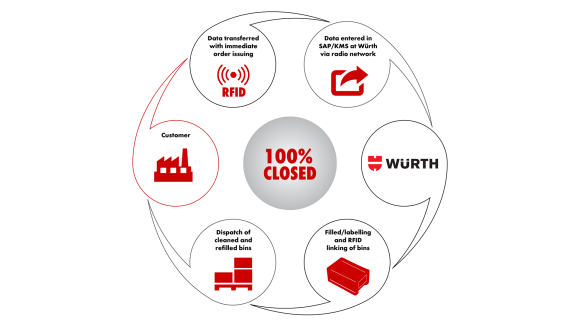

The principle of the Kanban system, which originated in Japan, is simple: it is a rolling two-bin system that, in contrast to traditional supply methodologies, provides C-Parts "just-in-time" directly at the point of use. The system can be easily adjusted if requirements or volume changes, simultaneously ensuring maximum delivery and supply security with reduced inventory levels and minimal capital commitment.

More on the kanban system and principleOur solutions for optimal Kanban control

The most suitable Kanban service solution for automatic replenishment is implemented, tailored to the respective items and the individual work situation and requirements. In all cases, the focus is on maximum availability of the right article in the right quantity at the right place and at the right time directly in production. With our diverse portfolio, we offer tailor-made systems that increase the efficiency of your company and optimize the material flow.

Kanban bins

Patented and safe

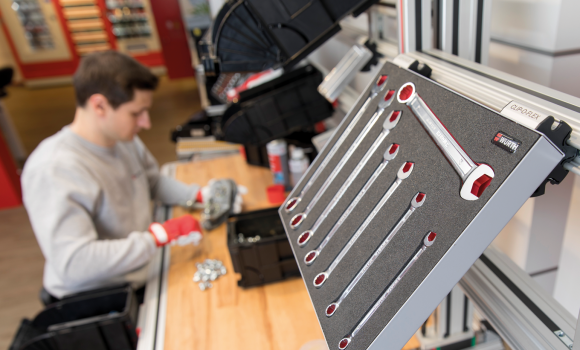

The large variety of items required leads to disorganization and overcrowded shelves in many production halls. Our Würth small load carriers in accordance with the VDA standard can be perfectly combined and offer optimum storage options for a wide variety of items. With our containers, you can make optimum use of your existing storage space.

To our Kanban bins

Kanban service

Individual and efficient

Refillment within a Kanban system is initiated depending on demand, taking into account your industry, your needs and your C-Parts requirements. We work with you to agree the level of service in the Kanban.

More information about the kanban service

Kanban information platform: WIS-Portal

The specially developed WIS-Portal offers you complete transparency in the Kanban process! Bin status, article location and filling quantities can be called up at any time with just a few clicks. Besides, the platform provides consumption analyses as well as turnover quantities and gives you access to material and test certificates, invoices, delivery notes, order messages and article data lists.

More about the WIS-PortalYour advantages

- Maximum availability of your c-parts in your production

- Transparent purchasing processes

- Reduced procurement costs

- Low capital commitment

- More flexibility within your value chain

- Precise control of the flow of goods

- Permanent traceability of your status within the Kanban system through the specially developed Kanban management software of Würth Industrie Service as well as the information platform WIS-Portal

- Just-in-time supply from the most modern logistics centre for industrial supplies in Europe in Bad Mergentheim

- Industrial assortment with more than 1,400,000 articles

- Personal advice from employees with industry know-how

You might find this interesting:

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.