Europe's most modern logistics centre for industrial supplies.

Reliable. Sure. Direct

Europe's most modern logistics centre for industrial supplies.

Reliable. Sure. Direct

Logistics centre for Europe: our linchpin

Delivery reliability you can rely on

- 70,000 m² of logistics area for maximum capacity

- over 700,000 storage locations for optimal product availability

- 235.,000 pallet storage spaces in the high-bay warehouse

- 34 km of conveyor line for smooth material flow

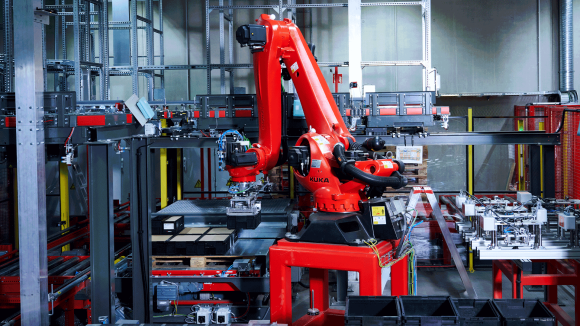

- 13 industrial robots support our logistics professionals

- 480 logistics employees at your service

Logistics efficiently and networked. People and machines working hand in hand.

Did you know? Interesting facts about our logistics.

New Standards: Photovoltaic System

Did you know? In 2023 we equipped the south facade of the new high-bay warehouse with an additional photovoltaic system. With a surface area of more than 4,600 square metres, over 2,000 modules and an output of over 1,000 kWp, the C-Parts partner has broken an essential record and is setting new standards. After all, the system stands out as one of the biggest photovoltaic facade systems in the D-A-CH region.

Find out more

Large Dimensions: High-Bay Warehouse

59,000 palette storage spaces on an area of 4,000 square metres with a height of 50 metres: With building dimensions at record level rarely seen in this overall complexity, the new automated high-bay warehouse marks a significant milestone in the company history of the C-Parts expert. As far as this type of construction is concerned, the impressive scale of the project not only sets new standards, but also sets a European record for the Kardex Mlog Division.

Find out more

RFID Kanban – Fully automated parts supply

In conjunction with the in-house developed Kanban management system, logistics forms the foundation for smooth Kanban processing and maximum supply security.

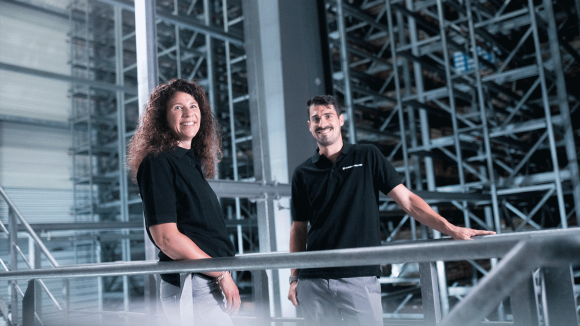

Find out moreWork in one of the most modern logistics centers in Europe – with us in Bad Mergentheim!

Logistics needs people who take action, experiment, think ahead, and give innovations a chance. People who are already thinking about tomorrow today. As a logistics employee, you work at the heart of our company. From here, we supply over 20,000 customers across Europe. Together with the entire team, you ensure smooth operations and the transportation of goods – from inbound delivery to outbound shipping and all the way to our customers.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.