Intelligent. Flexible. Future-oriented.

Intelligent. Flexible. Future-oriented.

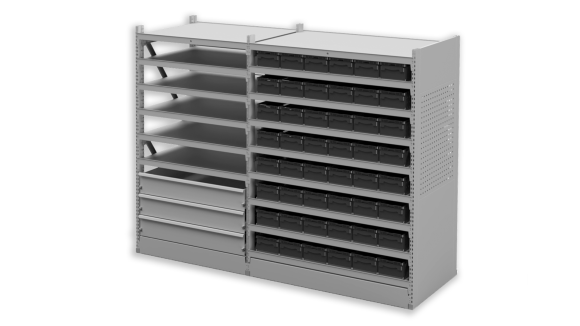

Kanban solutions for automated production supply – our innovations.

Since many years, the Kanban principle has proved to be an ideal solution for efficient supply of production resources. With the help of automated, demand-based reordering, it offers absolute supply security and reduces time and cost in the procurement process.

Together with our customers, we continuously evaluate which functional requirements arise in day-to-day production that further simplify the supply of parts in production. With the help of this knowledge, we continue to develop our existing solutions and introduce new systems in the market, which make even more application scenarios possible.

Kanban systems. The latest developments.

iTERMINAL, mounted directly on the Kanban rack, will hereafter show the customers a wide range of information about the Kanban rack at a glance, on one display. Especially the integrated item search function along with the digital rack label iDISPLAY can save a lot of time. We will be presenting this system, which will soon find its way into production facilities, for the very first time to the participants of the Expert forum C-Parts management to be held on 13th and 14th June.

You might find this interesting:

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.