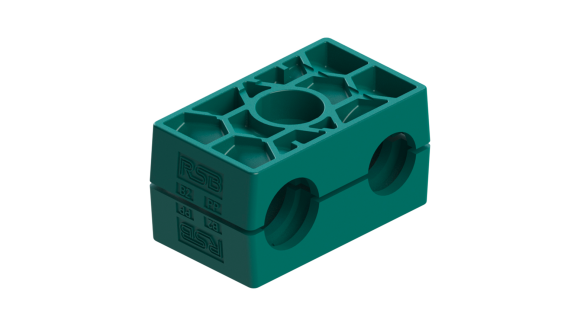

Ducting clamp according to DIN 3015

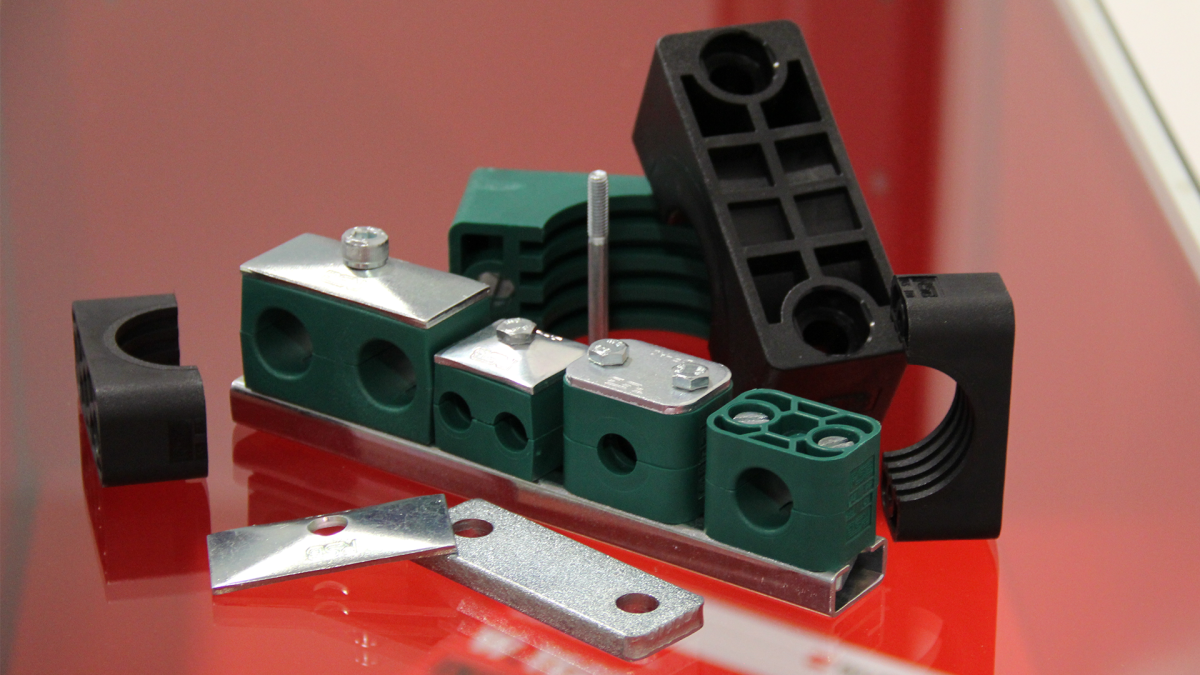

Ducting clamps are indispensable auxiliary materials for fastening pipes and hose connections. Cables or other components can also be easily and securely fastened with clamps.

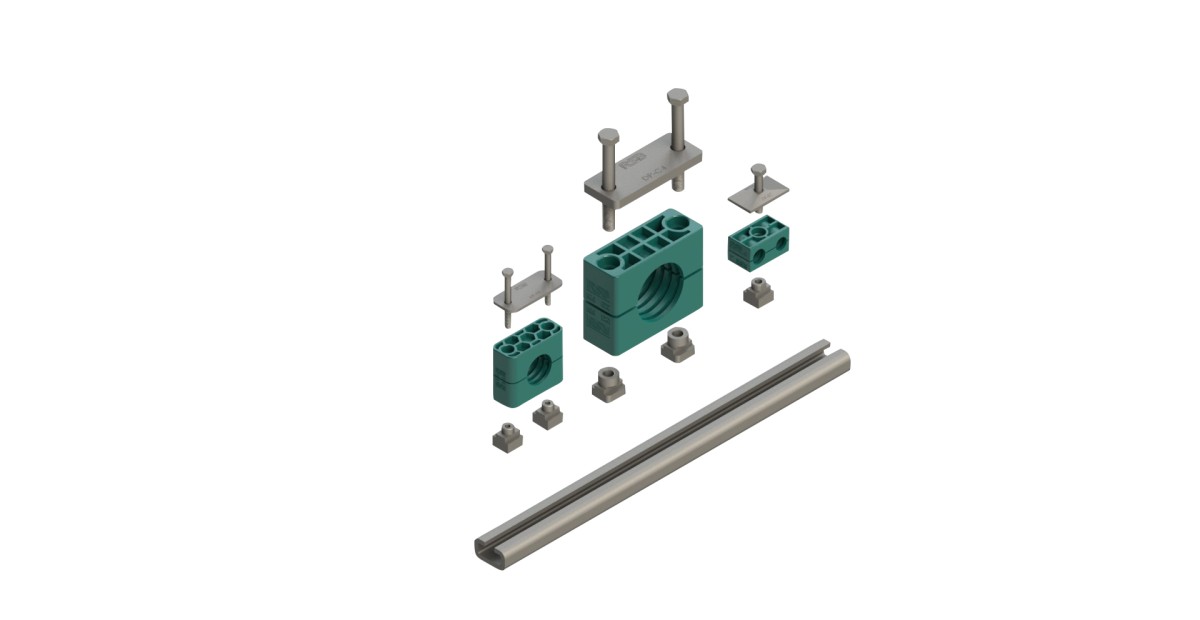

- Used for mounting on welding plates and on support rails

- Available in ribbed design for insulation against shock and vibration for pipes and in smooth design for holding hoses and cables

- For different diameters

- Made of polypropylene (PP) or polyamide 6 (PA)

It’s the inner surfaces that make all the difference!

Ducting clamps in ribbed design for fastening pipes

Ribs in the inner surface of the clamp absorb any impact or vibrations and also forces in pipe axial direction. The gap between the two clamping halves is used for prestressing the pipes.

Ducting clamps in smooth design for hoses and cables

It is recommended to use clamps with a smooth inner surface for holding the hoses and cables without prestressing.

Mounting instructions

The welding plates are welded on a base depending on the stress while observing the alignment of the clamps. Then the bottom half of the clamp is clamped to the welding plate, the pipe is placed and the second half of the clamp is placed on it.Then it is tightened using the screws.Extended welding plate can be screwed with the base. Do not weld with clamps made of plastic!

The support rails are available in four different sizes. They can be welded on or fastened by screwing a fastening bracket.

It is possible to mount multiple clamps of the same size on top of each other even with pipes with different diameters. This is done by using special mounting screws, which are locked using locking plates to prevent them from loosening. The bottom half of the clamp is clamped to the welding plate or the support plate and the pipe is laid. Then the upper half of the clamp is attached and tightened with the mounting screws that protrude above the upper half of the clamp. The mounting screws are prevented from loosening by placing on a tab lock plate. Afterwards, the second pipe clamp can then be placed on the mounting screw.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.