Customised development projects

With our one-stop approach, we guide you from the initial idea to the series delivery – efficiently, directly and without detours. Our comprehensive portfolio covers all the industries and offers you the flexibility to focus on your core competencies.

We specialise in assemblies and C- and B-Parts to ensure that your projects are implemented efficiently and successfully. You can count on our expertise and together, we will make your vision a reality.

Interactive visitor platform WISperience

Discover the world of Würth Industrie Service on our new interactive visitor platform! In addition to a company presentation and a 360° logistics tour, you can also visit a specialist exhibition on our product and supply solutions for efficient C-parts management.

More about WISperienceYou focus on your core competencies.

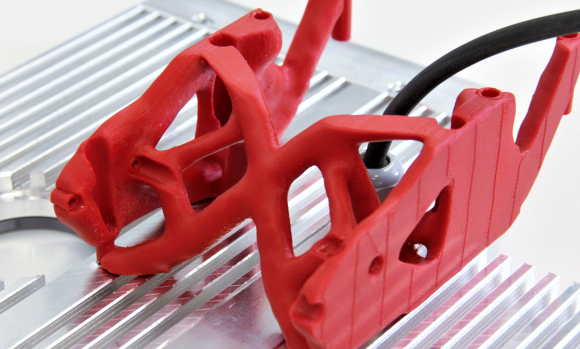

We develop innovative solutions for your C and B components and assemblies – from the initial idea to series production.

Keeping projects in view – Costs, appointments and quality under control

Development according to cost specifications is ensured:

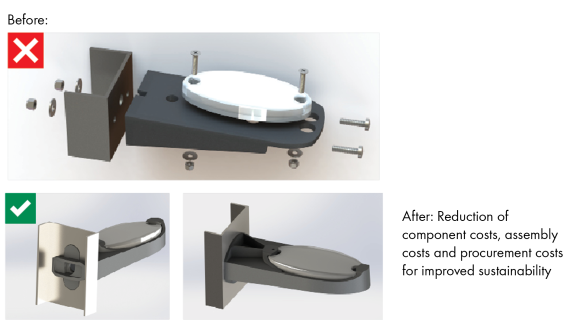

- Concurrent calculation tools from the assembly to the component

- A comprehensive portfolio ensures standardised integration of standard parts

A wide network of suppliers ensures standardised flexibility:

- Multitude of manufacturing possibilities for the optimal product

- Delivery reliability

- Option of international supply concepts

Integral component for project success to avoid and identify risks so that quality is not merely a coincidence:

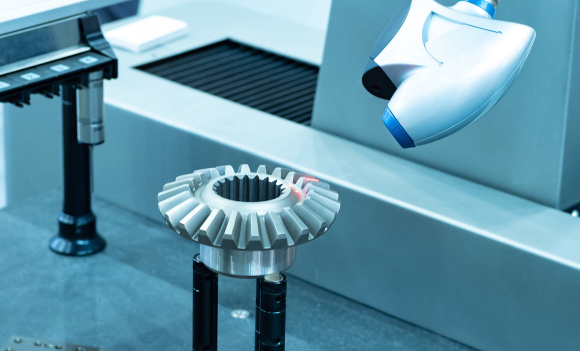

- Validation through internationally standardised supplier qualification

- Standardised initial sampling process with the possibility of customisation according to customer request

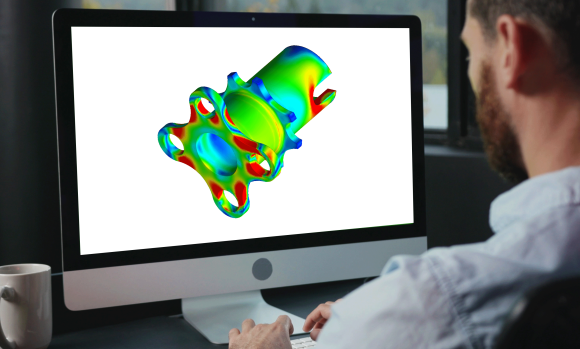

- Testing services for ensuring the specified product quality in product development

You might find this interesting:

- Flyer

Engineering services

Engineering services - Customised drawing parts

- Our Quality department

- Download centre with our

product and system brochures

product and system brochures

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.